A thermal clutch fan operates using silicon fluid as a viscous coupling medium. When the clutch is cool and disengaged, most of the silicon fluid is stored in the reservoir allowing your fan clutch to slip relative to your water pump shaft thereby spinning at a lower RPM than the water pump. This saves you money because the horsepower from your engine is not wasted driving a clutch fan when it's not needed. As your engine heats up, the thermal spring on the front of the clutch expands, which opens a valve allowing the silicon fluid to drive your clutch at an increased RPM. This provides more air flow through your radiator, preventing your car from overheating.

A non-thermal fan clutch is nothing more than a thermal fan clutch always partly engaged. It provides adequate cooling when needed, however, it does not save you money by disengaging (operating at a lower RPM) when additional cooling is not needed.

The engagement temperature varies model to model. Most automotive clutches engage between 70°C and 80°C air temperature at the face of the clutch.

These are the most common symptoms of a failed fan clutch:

- Engine overheating – with engine hot and ignition off, spin fan 1-11/2 revolutions indicates a worn clutch.

- Excessive Fan Clutch play – push the tip of the fan blade in and out. Any visible looseness in the clutch shaft means the bearing is worn.

- Greasy build up – Oily streaks radiating outward from the hub shaft or fluid leaking at centre of thermostat spring.

- Bad bearing - Seized, turns rough or has excessive play (more than 1/4" at fan tip).

- Freezing up – If the fan blade cannot be rotated by hand, or if hand rotation causes a harsh rumbling, the fan clutch bearing has failed.

- Shaft vibration – The fan clutch is mounted on the water pump between the water pump shaft and the fan. Any vibration can mean a worn bearing in the water pump o fan clutch. Since the fan clutch and water pump have about the same life span, it makes sense to replace both at the same time.

- Worn thermal spring - Spring is loose.

Some fan clutches will show no visible indication of a problem yet may still be faulty. The following may also indicate a faulty fan clutch:

- Fan spins excessively - Three or more times when hot engine is shut off.

- Poor air conditioning - At low speedor excessive high side pressures.

- Doesn't engage - Fan speed does not increase or "lock up" when the engine is hot.

- Does not disengage - Fan clutch won't slow down when the engine is cold.

Note; The fan clutch should be checked for possible replacement when a replacement water pump is being installed.

Each fan clutch type is designed to simulate the performance of the original equipment clutch that it replaces. All fan clutches are for specific applications and should be applied only on the application for which they are catalogued. Standard Duty Thermal Turns the fan 50-60% of shaft speed when engaged. Used with fans with lighter pitch fans. (1-1/2' of pitch) Flat plate impeller design with 30sq.in. of working area. Heavy Duty Thermal Turns the fan 80-90% of the shaft speed when engaged for increased cooling. Used with deeper pitch fans (2 1/2" of pitch). Land and groove design with 47sq.in. of working area allows higher operating RPM. Severe Duty Thermal Turns the fan 80-90% of the shaft speed when engaged. Used with deeper pitch fans. (2-1/2" of pitch). Land and groove design with 65 sq.in. of working area. Larger working surface provides cooler running and longer life expectancy.

Yes, most fan clutches allow the fluid to drain into the working area when shut down and engage the clutch. At starts it may take 1-2 minutes for the clutch to slow down.

Generally, we recommend the use of the EWP®80 (Part No. 8005) on engines up to 3.0 litre capacity and the EWP®115 for larger engines. Both EWP® Electric Water Pumps fit most makes and models and mount into the bottom radiator hose and are complete with all the necessary components required for easy installation, with a comprehensive DIY instruction booklet.

Both the EWP®80 and EWP®115 are performance accessories that increase power sent to the drive wheels, while improving cooling capacity and fuel economy and eliminating engine heat soak after a hot shut down. Old mechanical, belt driven water pumps run directly off the engine and sap engine power. The engine cooling is improved with a EWP® by having a higher flow rate at idle and low engine speeds when there is little or no ram air, and when the engine is switched off. But the important improvement for a race vehicle comes from the fact that the power the mechanical pump takes from the engine increases as the cube of its speed - so when the pump speed doubles from idle speed say 600 rpm to 1200 rpm, the power it takes increases by 8 times. Then another 8 times going to 2400 rpm and so on up top 10,000 rpm. It is this extra power and torque you are releasing by disabling the mechanical pump, that goes to the drive wheels. Both Electric Water Pumps can be hard wired into your electrical system or you may opt to use the Digital Controller (Part No 8020) which will greatly enhance your control of coolant flow and engine temperature.

If you choose to use the Davies Craig Digital Controller you should remove the engine’s thermostat – the Controller is the new “thermostat”. The Digital Controller allows you to electronically set the engine target temperature and it adjusts the rate of coolant flow, hunting for, and then locking onto the temperature you set. You have five (5) options; 70c, 75c, 80c, 85c and 90c for either economy or performance, unlike your thermostat, which is set at one temperature by the engine manufacturer

Both EWP®80 and EWP®115 Electric Water Pumps fit most makes and models and mount into the bottom radiator hose. You just cut out 100mm (4 inches) of hose and let the EWP in. The existing water pump housing is still required as an inlet into the engine block, or a blanking plate can be manufactured to bolt up to the block with an inlet for the radiator house to replace the old pump. It is recommended that you do not ‘hard mount’ your Electric Water pump. When firmly fixed to the chassis or engine, the EWP® may bow which disturbs the shaft seal and may cause a leak and not reseal when the EWP® cools. The EWP®115 weighs only 980 grams, therefore the radiator hose is more than capable of holding your lightweight EWP®. Should it be necessary to mount the pump we recommend you use rubber ‘cotton reel’ type mounts to help cushion the pump against vibration and you can use the extra holes around the perimeter of the base of the EWP for this purpose. A supplementary mounting plate can also be used for mounting purposes. Both kits come complete with all the necessary components required for easy installation and a comprehensive DIY instruction booklet.

If you want extra power and fuel savings you will need to remove or disable your existing mechanical belt driven water pump . Alternatively you may wish to keep your existing mechanical pump and use the Electric Water Pump as an auxiliary pump.

Both EWP®80 EWP®115 Electric Water Pumps fit most makes and models and mount into the bottom radiator hose. It is recommended that you do not ‘hard mount’ your Electric Water pump. When the EWP® heats up the body of the pump will expand slightly. If the EWP® is located in the hose only, the expansion is no problem. When firmly fixed to the chassis or engine, the EWP® may bow which disturbs the shaft seal and may cause a leak and not reseal when the EWP® cools. The EWP®80 weighs only 800 grams and the EWP®115 weighs only 980 grams therefore the radiator hose is more than capable of holding your lightweight EWP®. Should it be necessary to mount the pump we recommend you use rubber ‘cotton reel’ type mounts to help cushion the pump against vibration.

Customers with large race engines are having great success with two EWP®s mounted in line. One is controlled by a Davies, Craig Digital Controller (Part no 8020) set to its target temperature and wired to the ignition. The other is run by a standard on/off thermal switch (part no 0401) wired direct to the battery, and set to cut in at a few degrees hotter than the Controller target temp. When the Controller is running the first EWP® at full speed and the engine temp still increases, the Thermal Switch kicks in the second EWP® and runs it until the engine temp drops 4◦C. in the same way an electric fan is controlled. When the engine is shut down hot, the second EWP®, being wired direct to the battery, will run until the engine cools. The same Thermal Switch used to run an electric radiator fan can be used for the second EWP®. In this case, make sure the fan and EWP® are wired directly to the battery. Both the fan and the EWP® will run on hot shut down, typically for as little as 20 seconds, to cool the engine.

The size of correct application for electric fans vary greatly with each type of vehicle. Firstly consult your Davies, Craig selection guide. If the vehicle is not listed then measure the available radiator core area and space in the engine compartment between the radiator and the water pump or in the front of the air conditioning condenser. Then consult your Davies, Craig catalogue for the recommended fan sizes. Generally the larger the engine the larger the fan required. Upgrade to a larger size if yo have a turbo or plan to tow.It is important to follow these recommendations to ensure that you will get adequate cooling even under severe driving situations.

Davies Craig recommends you fit an EBP® Electric Booster Pump part no 9001, to engines equipped to run on LPG where a constant flow of coolant is essential to ensure the LPG regulator does not freeze up on a cold start. This very compact unit fits in the engine’s heater hose lines and offers up to 20 litre/min of coolant flow.

The extra current is very little. About 90% of total motoring time the EWP will run at 10% of its maximum speed using about 2 amps. Being in nylon, the impeller can have aerofoil cross section and the tip clearances can be very small. A mechanical pump has to perform at 600 rpm and 6,000 rpm and it cannot be efficient at both these speeds and all speeds in between. Furthermore, as the power the pump requires to operate increases as the cube of the speed - when the mechanical pump is operating at the higher speeds, as it does, as a car passes through its gear range, its ‘robbing’ engine power in the order of 6 to 10kW. The EWP® which uses at maximum speed 9 amps x 13 volts gives 120 watts at say 30% efficiency from the alternator to hydraulic power means about 0.4 kW to drive the EWP®, when it does operate at full speed

No, Davies, Craig Thermal Switch (Part No. 0400, 0401 & 0404) must be mounted in the engine compartment near the radiator.

We offer other switches which can be mounted within the car cabin, these include part 0444, 0445, 0500, 8002

Yes. Davies, Craig electric fans work in either position as they are reversible.

Our Thermatic Fans are built initially upstream applications (in front of the radiator) as this method is slightly more efficient.

The instructions will show you how to set up the Thermatic Fan in Upstream and Downstream applications.

The "pump too fast lose less heat” notion is very popular and many experienced mechanics are very attached to it but – it is a fallacy. Davies Craig has been carrying out research and development for over a decade on a number of projects and has never been able to pump genuine liquid coolant faster and lose less heat. In all car engines, when the mechanical pump reaches cavitation speed, coolant turns into a gaseous state which is compressible,(liquid is not) and the real flow rate of liquid coolant drops even though the mechanical pump has a higher rpm, and so heat loss drops. The engine temp then rises. And it only seems like the flow rate is too fast, and the coolant is spending too little time in the radiator to lose its heat etc. etc..

Where there is a thermostat bypass in some engines including those produced by BMW & ROVER, there may be a bypass from the thermostat housing back to the water pump chamber so when the thermostat is fully closed, coolant passes directly from the engine block to the thermostat housing and then straight back to the block without passing through the radiator. When fitting your EWP® to an engine which uses a bypass valve style thermostat, after you have removed the thermostat, you will need to block off the bypass passage (with a core plug or similar), to prevent flow from your EWP passing directly back to the radiator without passing through the block.

One of the very important factors with engine cooling fan/s is the volume of air any specific Thermatic Fan can pull or push through a radiator. In general terms 2 x 14" fans will match the volume flow of 1 x 16” fan but not 2 x 12" fans. There are other factors including core thickness and clearly the thicker the radiator core a more powerful fan is required. Therefore a single 16” fan will out-perform 2 x 12” fans in almost all situations. E.G. If your radiator is 4 core or greater then 2 x 12" fans wouldn't be recommended. Therefore 1 x 16" fan could be sufficient.

Remembering that any Thermatic Fan will cease to be effective once the vehicle speed has reached 50-60 KPH after which the ram air takes over. We also recommend Thermatic fans be fitted to the downstream (engine side) of the radiator

The EWP® is designed for maximum efficiency at its maximum speed of 2250 rpm. Being in nylon, the impeller can have aerofoil cross section which gives lift and the tip clearances can be very small. The mechanical pump has to run at 600 rpm and 6,000 rpm and it cannot be efficient at both those speeds and all speeds in between. Furthermore, as the power the pump takes increases as the cube of the speed - when the mechanical pump is operating at the higher speeds, as it does as a car passes through its gears; it is taking power of the order of 6 to 10 kW. The EWP® uses at maximum speed, which is usually less than 20% of total motoring time, 9 amps x 13 volts gives 120 watts at say 30% efficiency from the alternator to hydraulic power means about 0.4 kW to drive the EWP®. The EWP® never needs to run at very high speeds where the mechanical pump is consuming high power and torque. In addition, with the old mechanical pump and a thermostat set up, the thermostat is partly closed most of the motoring time and in a cool climate at highway cruising, it is about 90% closed. As a consequence, the flow and pressure being generated by the mechanical belt driven pump and paid for with power and torque, are choked at the thermostat and wasted. This system has worked reasonably well for a long time but it is not smart. With your EWP and digital Controller, power and torque is never wasted as there is no choking (no thermostat) and only as much flow and pressure as is required is produced. We are starting to see the allowance of EWP® s in racing mostly for the extra power but also to prolong the life of engines with the run on after hot shut down to eliminate heat soak. In any case we cannot stop progress, nobody in racing runs drum brakes or cross ply tyres these days!!

The adjustable thermal switch thermostat is a temperature control device which senses the temperature of the coolant as it leaves the engine,radiator and turns on the electric fan(s) when cooling is needed. The thermal switch thermostat is adjustable through a wide range of temperatures by turning an adjustable screw located on the controller.

With respect to the EWP fitment in the top radiator hose, there is no negative effect, reduced EWP motor life etc. What is critical however, when the EWP is fitted to the top hose the system MUST be FULLY bled and NO AIR is to be left in the system at any time. The EWPs are not self-priming pumps and as such, should the EWP be operated dry, premature failure of the seals may occur. The reason we nominate the bottom radiator hose is this very good reason as listed.

As the EWP is positioned within the bottom radiator hose, the EWP is a universal fitting pump. The EWP kit comes complete with a range of adaptors to fit hose sizes 32mm to 50mm or 1 ¼“ to 2”.

The probe from the 0444 can be used within the radiator fins measuring thermal air temperature or installed it into your water / coolant system.

The ideal operating engine temperature is dependent on the type, size, capacity, workload and environment the engine is working in, however the best engine temperature is usually between 85-105°C or 185°F-221°F.

Generally when the fuse holder is melting it indicates that either the wiring loom used between the fan and the switch or relay is an incorrect gauge or the motor on the fan may have an internal fault. If you have used a smaller fan than a Davies Craig 16" Fan or you have used a different brand fan before fitting the Davies Craig 16" Fan and you are using the previous fans wiring then this wiring may not be the correct gauge to carry the current our 16" fan produces. The Davies Craig 16" Fan is the only fan in our range that has a heavier gauge wiring loom than the others as it produces a lot more current than the others and requires heavier gauge wiring so the wiring doesn't overheat.

The max current draw to operate the EWP80 is 7.5A and the EWP115 is 10A. However under average operating conditions the current draw is approx. 2A and 3A respectively.

The Digital Controller (Part No. 8020) is Davies Craig’s recommended method of operating both models of the EWP. However it’s not the only method of control.

If the EWPs are to be used in motor racing or drag racing, you can run the EWP continuously, due to the extreme amount of heat produced under those conditions. If your race engine runs too cold, upgrade to the Controller.

The EWP may be used with a Davies, Craig Thermal Switch (Part Nos. 0401 and 0402) as an auxiliary pump. If the EWP is the only pump in the engine it should not be run with an on/off thermal switch like a radiator fan. Your engine needs some flow all the time or hot spots will form outside the cylinders.

As for the fuse blowing when you use the A/C switch, this either indicates the use of an incorrect fuse or maybe an internal fault with the electric motor. You should be using a 30amp fuse in the wiring loom from the 16" Fan Kit and a 25amp supplied fuse in the wiring from the Electronic Controller.

A fan with curved or swept blades is quieter than a straight blade fan but it does not move as much air. Also the weight of a ring connecting the tips of a blade takes power to rotate. We think it is more important to have as much air flow as possible rather than a slight reduction in noise, when the fan is running which is generally less than 5% of total motoring time.

Davies, Craig performed a number of tests which concluded that a normal water pump uses up to 10kW of power to operate at its high speeds, therefore if it is removed this power is saved and sent to the drive wheels. Not all the power gained will be transferred directly to the wheels as a small percentage will be lost through the drive-train. Each engine is different and the size, capacity and performance of the engine will determine how much power will be gained. Generally higher revving engines such as small capacity and rotary engines will have the biggest percentage increase in power and torque. With the extra power, maximum engine speed will increase so you should be careful that other engine components can handle the extra rpm. A Dynamometer test on the 5.0L V8 VT Commodore measured a 10kW improvement at high rpm and overall increase in torque particularly in the lower rev range.

When the ignition is first turned on, the Digital Controller will 'system check' the EWP and it will run the pump for approx 10 seconds. The Digital Controller supplies a six volt PWM- pulse width modulation, (10 seconds on – 30 seconds off) to the Electric Water Pump from a cold start until the engine temperature reaches 20◦C below the target (set) temperature. At this point the Digital Controller then supplies a PWM (10 second on – 10 seconds off) till 5C less, then the Controller will ramp up to full system voltage as and when required searching for and locking onto the target temperature.

- Electric Thermatic Fan/s will deploy at +3◦C above target temp.

- If the engine cools below the target temperature, the Controller will step back from full system voltage down to 6v if necessary and generally it will go back to pwm when highway cruising.

The Digital Controller will indicate when;

- The EWP® is running

- The target (set) temperature is reached

- The supply voltage is too high or too low

- The EWP® is running at full supply voltage and is not holding the target temp (Thermatic Fan/s need to be turned on)

- There is no power to the EWP®

- If you wish, you can look at what the Controller is supplying the pump by connecting a voltmeter to the EWP® motor leads. But remember when the Controller is in PWM mode, the meter will flicker.

Major advances in the new Digital Controller:

- Temperature settings are now electronic in that the SET temperatures are now easily set digitally at the touch of a button.

- An automatic time-out has been built into the Controller to run the EWP to the target temp or for a maximum of 2mins after ignition OFF, to eliminate the effects of heat soak on engine shutdown. Generally the EWP® will run for less than 2mins because heat soak washes out in about 20 seconds.

- A suite of self diagnosis functions has been built into the Controller which will identify cooling problems enabling easier trouble-shooting.

- The Controller has a number of monitoring features to keep the user appraised of system operation conditions at all times e.g. Controller on, pump operation mode, cooling system temperature etc.

- A new option for mounting the temperature sensor into the top radiator hose is offered in lieu of placing the sensor wiring between the hose and housing or into the thermostat housing. Part no is 0409.

- The current carrying capacity of the Controller has been increased from 7.5 amps to 12 amps in conjunction with a significant weight reduction.

- A 'Test' function has been adopted which gives the user a visual warning -- on the Controller and remotely -- if a system problem is evident.

Yes, as you haven't connected/installed the EWP yet you will need to close the circuit on the EWP 'T' connector. This is simple, take the small led light supplied and secure one of each end into each of the 'T' piece pins. This will now send a signal to the Digital Controller that the EWP is ‘connected’ and the Controller will execute this function correctly, engaging the Thermatic Fans at 3°C above the 5 set/targeted temperatures you have programmed into your Controller.

The EWP & Fan Digital Controller (part no. 8020) is primarily designed to run the EWP with the added function to switch on and off your Electric Fan, which saves you the cost of having to purchase an additional electric fan switch. If you are not using our EWP then we would recommend against purchasing the EWP & Fan Digital Controller as you primary fan controller as you can't independently set the cut in temp for the fan. The EWP & Fan Digital Controller is programmed to switch on the fan at 3°C above the EWP temp setting. For a fan only application we would recommend using either our Mechanical (part no. 0401) or Electric (part no. 0402) Thermatic fan switch and wire direct to the battery so the fan will run on after engine shutdown.

The 0409 kit comes with adaptors to suit inside diameter hose size of 30-35mm, if you have 36-42mm inside diameter hose then you need to use the 2 rubber sleeves over the adaptor to allow for the larger hose which are included in your kit. If you have 42-51mm inside diameter radiator hose, you can contact us and we can provide you with larger rubber sleeves to accommodate your needs.

We do not keep records on each and every vehicles top radiator hose dimensions and therefore leave it up to the customer to measure their radiator hose size and advise.

We don't sell a range of 6V thermatic fans for vintage cars however if you were to run our fans off a 6V battery they would run at half the speed and still would provide enough cooling for a vintage car. To compensate for the reduce in speed you may consider going up in fan size?

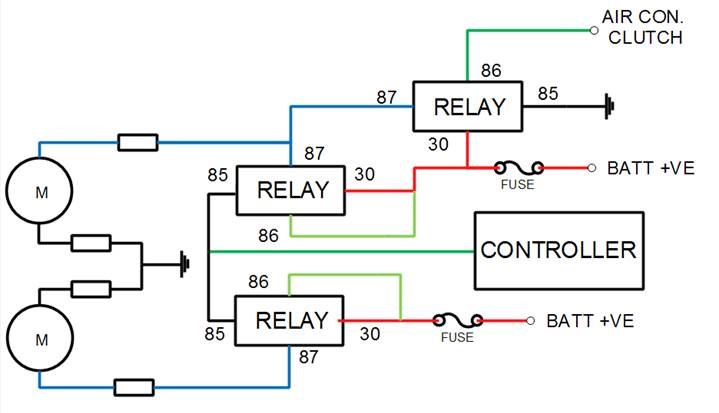

Please check the wiring of the fan relay. The green wire with the black trace from the Digital Controller to the fan relay is a negative switching wire. Therefore from relay pin 85, this wire should be connected to the positive battery terminal either directly or through pin 30. See attached diagram.

Davies, Craig P/L conducted tests which showed that each capacity engine had different coolant flow rates i.e. V8 was more than a 4-Cyl. One common V8 has a flow of 24 l/min at idle (600 rpm) and so about 240 l/min at 6000 rpm. That is 240 kilograms of coolant being rammed through narrow radiator tubes every minute. It takes a lot of power to do that. However it was shown by the CSIRO that in a standard engine, flow above 80L/min increases heat loss by very little. Once the flow has reached a rate where all of the heat being produced by an engine is being dissipated in the radiator there is no benefit from pumping faster.

An engine requires a certain flow when it is idling and the vehicle is stationary in high ambient temperatures - say 15 L/min. The flow rates at higher engine speeds are a consequence of the idle flow and are roughly proportional to the increase in engine speed above idle. Invariably the flow rates at high engine speeds are much more than is required given that high engine speeds are transient, as the engine passes through gears, or the vehicle has high road speed and so there is high ram airflow through the radiator. Heat loss is a function of coolant flow and air flow and you do not need both to be at their maximum as the system is designed to maintain engine temperature with both at their lowest values. But you have to have those high coolant flow rates because the mechanical pump speed is a slave to engine speed and if you have 15 L/min at 600 rpm, then at 6000 rpm you will have about 150L/min. That is 150 kilograms of coolant being rammed through the radiator tubes every minute – it takes a lot of power to do that.

The cooling is improved with a EWP by having a higher flow at idle and low engine speeds when there is no or little ram air, and also when the engine is off. But the important improvement for a race vehicle comes from the fact that the power the mechanical pump takes from the engine increases as the cube of its speed - so when the pump speed doubles from idle speed say 600 rpm to 1200 rpm the power it takes is 8 times. Then another 8 times going to 2400 rpm and so on up top 10,000 rpm. It is this power and torque you are releasing, by disabling the mechanical pump, to go to the drive wheels.

The Davies Craig Electric Water Pump, material specifications; Standard PA66 GF30. Thermal properties, continuous working temperature = 135°C, Peak Temperature = 160°C.

Yes, the range of Davies, Craig Electric Water Pumps are precision manufactured using Nylon 66, reinforced with 30% fibre glass capable of withstanding various types of inhibitors widely available on the automotive market. This same tough material has been tested and approved by many automotive manufacturers and is the same material designed into the manufacture of radiator side and header tanks adopted by a good number reputable automobile manufacturers worldwide.

Our EBP (Part No.9001) will adapt to 1" hose. While the inlet and outlet is only 19mm (3/4") many of our customers have used this very efficient pump on 1" heater hose lines.

If you have access to adaptors you can order Part No.9002 which is our 'short' EBP, supplied with the wiring loom and without the fittings.

You can run the EBP at constant 6V, some early cars had 6V systems. Obviously it will only deliver 10 litres per minute instead of the usual 20 litres per min. All our EWPs can be operated at any voltage up to 15 volt, although the 15 volt operation is not recommended for long periods.

On the other hand, not so the Digital Controller, it MUST be operated at 12 volt and if an over-voltage situation occurs the unit may malfunction.

The adjustable thermal switch ostat is a temperature control device which senses the temperature of the coolant as it leaves the engine,radiator and turns on the electric fan(s) when cooling is needed. The thermal switch ostat is adjustable through a wide range of temperatures by turning an adjustable screw located on the controller.

No, your old wire leads will cause the controller to play up it is not recommended to wire the leads to the ignition coil.

To get the controller to work, you will need to install new leads and use an ignition switched source.

This depends on the vehicle and what the vehicle is used for? Generally for short circuit race/drag applications and engines used under extreme conditions we recommend removing the thermostat to provide the greatest cooling capacity. It is always recommended to use the controller for other applications, however if you have decided not to then we recommend to drill a small 5mm hole in the thermostat to allow some flow and release of back pressure when the thermostat is closed. You may find in these circumstances that the engine temperature is not managed effectively and also the pumps life will be reduced if the controller is not used.

This is dependant on the type EWP being used or your set up. The EWP Digital Controller can't handle the total current of 2 x EWP115 in parallel however it will handle 2 x EWP80's. However if you run the second EWP115 off the fan output through a relay it will run both, but the second pump will only switch on and off 3°C above the set point, not via PWM.

The Davies Craig Digital Controller will operate with most other billeted/bolt-on OR remote-mounted Electric Water Pumps currently marketed around the world. Check that the output (current draw) required by CSR pump does not exceed 12 amps. From our records the current draw for most CSR pumps is around 5.8 amps. Check the output of your unit before proceeding. Please ensure you use the temperature sensor supplied with the Digital Controller as this unit has a programmed resistance to function with this specific Controller.

We believe you may have your Digital Controller incorrectly wired. The black stripped thin green wire from the controller is a negative input wire, it has to be connected to relay at pin 86 as per the diagram within the instructions. In order to cut-in the fan, the pins 85 and 30 from relay must be connected to Positive power source as per the instruction diagram.

Like a computer, the Digital Controller can be stored for lengthy periods and your settings will not be effected.

At worst, it would return to the default setting of 85 Degre

No problem extending the Thermal Sensor cable. Be sure to use the same gauge wire to ensure you don't upset the electrical resistance of your EWP engine cooling system. Please note, depending on the length of the extension, it could lead to a delay reading the actual engine temp.

Your EWP/Fan Digital Controller has an in-built memory, a micro-processor which, among other features, maintains your targeted/set temperature once you've programmed your setting into the Controller. This setting will never be lost unless you totally disconnect the Digital Controller in which case the unit will revert to the factory 'set point' of 85C/185F. Your cut-off/battery isolator will not affect your 80C setting. Further, to check your set/targeted temperature you simply press the white button when the unit is reconnected and/or you turn on the battery isolation switch and the temperature LED will advise you of this set temperature.

The correct application for any vehicle depends on a number of variables such as the type of vehicle, if there is a load the vehicle will be expected to pull of carry and the climate and terrain the vehicle will be operating in. Always consult your Davies, Craig catalogue for the correct application.

For some vehicles customised mounting brackets are provided in the kits ie. Ford EF Falcon, EA to ED Falcon, Commodore VN to VS.All other applications will use the universal mounting kit. Maximum efficiency is achieved when the cooler is mounted to the condenser or radiator to receive the coolest air and the maximum amount of ram air as well as fan air. This is usually directly in front of the radiator or condenser. Consult your Davies, Craig selection guide.

The Davies, Craig cooler may be mounted with the hose connections in any direction as long as they do not cause the hose to bend too much. Our recommendation is a minimum bend radius of 75mm.

The amount of cooling depends on the vehicle, cooler size, type of cooler, mounting location and ambient air temperature. Most transmission coolers, when properly selected and installed will achieve at least 10°C to 30°C drop in fluid temperature with a 20°C drop being average. Every 10°C drop in temperature can double oil and equipment life.

Our EBP (Part No. 9001-9002) and our Digital Controller (Part No. 8020) can not be used for a positive earth vehicle.

However our EWP80 & EWP115 models can be used in positive earth applications / vehicles, you have to simply reverse the polarity of the pump wires.

Example:

- For our 12 volt EWP80 and EWP115 the wires are Blue (positive), Black (earth), simple reverse this wiring in your applications thus Blue wire becomes Earth and Black becomes Positive.

- For our 24 volt pumps, the wires are Red (positive), Black (earth), simple reverse this wiring in your applications thus Red wire becomes Earth and Black becomes Positive.

Therefore you can run these pumps constantly on from ignition or you can use them with our Mechanical Thermal Switch (Part Number 0401 & 0404) which will switch the pumps on and off at the desired temp. You do lose some functionality in not being able to use the Digital controller (Part 8020).

We always recommend adding a transmission oil cooler when using the vehicle for towing. You can either use our oil cooler in series with the factory fitted cooler or by-pass the factory cooler and use ours solely. We have come across many reports of users having problems with factory fitted oil cooler built into the radiators failing and causing water to leak into the transmission and vice versa causing transmission failures therefore a lot of customers are by-passing the factory cooler and relying solely on our coolers to do the job.

We no longer make this specific oil cooler for the EA Falcon. We recommend you use either of the Universal fit type. Part# 676 for 4 cylinder engines, part# 677 for 6 cylinder engines or part# 678 for 8 cylinder engines or any car used for towing.

Obviously engine all has varying amount of viscosity depending on the oil rating. In general engine oil is a lot more viscous than transmission fluid and therefore a transmission oil cooler is not recommended for cooling engine oil. The main reason for this is that the pipes in a transmission cooler are narrower than in an engine oil cooler and the viscosity of the engine oil will cause a greater resistance in the cooler and build up more pressure making the transmission cooler inefficient.

I would strongly recommend to relocate the EWP Controller sensor to the same location or as close as possible to the vehicles temperature sensor so the 2 sensors are both reading from the same location. It is not uncommon for temperatures in different zones of a cooling system to vary by 10-20 degrees C and this temperature difference between the two sensors may be what's causing all your issues. Relocate the sensor and if you still have issues please let us know.

There is no performance difference between our EWP115 Nylon and EWP115 Alloy. Only the outer housing is in different material.

EWP115 Nylon

Pros: - lightweight (980 grams or 2.16 lb.)

Cons: - No thread on the inlet or outlet to fit screw-in style hose or AN fittings.

EWP115 Alloy

Pros: - Cast alloy housing can be polished for a shiny look.

- Has AN -16 thread on the inlet and outlet to enable the fitment of screw-in style hose fittings.

Cons: - Heavier than nylon version (1151 grams or 2.56 lb.)

This EBP has its own built in voltage regulator to regulate & smooth the input voltage. As you mentioned earlier that the customer is using a AC to DC transformer & a bridging rectifier circuit, indeed he need to use an appropriate capacitor. I cannot give you any values for the capacitor which he need unless I see the full circuit. But as an example if he is using a bridge rectifier of 1N4148 then 220uf capacitor will do the job.

The TPMS will monitor the air pressure and temperature of up to 22 tyres with a pressure range of 0 to 145 psi as long as the furthest sensor is no more than 7.6 meters from the monitor. You can increase the range by a further 8 meters using a booster (Part No. 1020) as a mid point link to the monitor and the furthest sensor.

The sensors are screwed onto the valves - the exact same way the valve caps are currently screwed onto the head of each tyre valve. The valve would have to fail in the first instance and this would alert the sensor to a tyre pressure variance and would therefore sound the alarm as well as signal the flashing red led light on the tyre monitor located in the vehicle.

The standby mode/sleep mode is when no action is being taken with the monitor and the backlight of the screen dims. All you will see then is an outline of the vehicle. However whenever you press a button, open the car door or make any sudden movement the monitor will generally light up as it is motion sensitive. The term we use for standby mode is the mode other than alignment or standard pressure setting mode. You will know when you are in standby mode, 1, you will only see the tyres of the sensors you have aligned and 2, when you press the left or right button it will scroll through each wheels current pressure, then current temperature, then move to the next wheels current pressure, then current temperature and so on. Whereas in standard pressure setting mode pressing the left or right buttons will increase or decrease the pressure setting of the current wheel selected. Therefore theoretically there are 2 modes in standby mode. The monitor will go to sleep but still be active when no action is being taken in standby mode.

The monitor will never power off unless the battery goes flat or you physically power it off by pressing the centre button in standby mode for 8+ seconds. Initially you will hear a beep after 5 seconds, but continue to hold the button down for a further 3+ seconds and the monitor will eventually completely turn off. When the monitor is in standby mode, if no action is taken with the monitor for approx. 5 seconds the backlight will go out and the monitor will be in sleep mode so to speak, to save on battery power. This does not mean that the monitor is off and I think this is where the confusion is? You may believe the monitor to be off but in fact it is only asleep and is still receiving signals from the sensors and providing a warning when necessary.

No, this shouldn't create any problems as it has a rechargeable battery. The only reason you need a power supply is to recharge the battery or keep the battery charged. So whether it is linked to the ignition or not should make no difference.

This is an excellent idea and we encourage those users who plan to travel off-road using their TPMS Sensors that they use some insulation tape to further protect TPMS Sensors from any damage. Will the addition of tape disturb the wireless signal from the Sensor to the TPMS Monitor? No.

If the display on monitor is always flashing with 0--0 and battery icon, please return it to the place of purchase for a warranty claim.

When you first install any thermal switch, make sure you run the car engine up to temperature or at least 110°F before trying to adjust the temperature switch. Please use the instructions for the correct set up procedure. Should the fans still not come on after instructions have been followed, please contact customer services for further assistance.

The new LCD Controller, Part number 8000 is compatible with the old controller, part 8020. The connectors are compatible, plug and play essentially. The main feature of the LCD unit are more information on the screen as well as the ability to run 12 & 24 Volt systems, audible alarm, expanded temp range 60-100c. The unit comes out of the box with a default setting of 85 degrees.

Yes.

You will need to ensure your probe is 6mm to be compatible with the compression nut/body/olive assembly supplied with this kit.

Or, if you are going to install a Thermal Sensor Sender unit the thread in the nylon Adaptor is ¼” NPT and this needs to be compatible to your sender unit.

Our TyreGuard 400 uses RF (Radio Frequency) signals to transmit the Sender/Receiver signals.

These are two possible reason the RF signal could be jammed.

- Using uncertified (CE) chargers/cables / power adaptors around the TyreGuard monitor.

- Using broken / damaged/ open / cables – wires

These can easily create EMF (electromagnetic field) which will easily damage / drop the RF signals.

- Place a different sensor on the same Tyre you are having issues with, please confirm if the sensor is picked up by the Bluetooth device and the app on the phone.

- Test the faulty sensor on another Tyre, does it work?

*Note: on your app, the sensors will appear in the location they have marked on the casing, not where you are testing.

Need to eliminate the possibility that the Tyre / valve has an issue.

When you screw the sensor onto the wheel, need to hear a little bit of air released from the valve.

- Next, I would also try changing the battery with one of the sensors you know works, just to make sure you don't have a faulty battery in a new pack (it does happen)

- Finally, un-install the app, remove the sensors and the Bluetooth device and re-install everything from the start.

If after all this you still have issues, contact us.

PLEASE MAKE SURE you DO NOT cut the Sensor / Probe wiring to shorten or extend while installing. This action interferes with the resistance signal to the control box and subsequently an 'err' message will appear.

The switch will be completely useless and not serviceable if you cut the wiring.

We suggest you wind up the wiring should you need a shorter the lead.

You can extend the power wiring then relocate the switch to a location where you would like the sensor fitted.

A customer was happy to share the process they used to connect a 3/4" pump hose to a 35mm radiator hose.

From the left to right, there is a barbed fitting for a 1 1/4 " hose w/ threaded female connector (the 1 1/4 is close enough to 35mm). Next is is a threaded 1 1/4" male fitting, with the other end being a 1 1/4" slip fitting. I will glue into that a bushing, 1 1/4" male by 3/4" threaded female. Finally I will screw in a 3/4 inch threaded/barbed connector, which will fit into the pump hose.

Mobil Dextron VI (6) is a high-performance synthetic blend of ATF designed to meet the service requirements of General Motors’ range of automatic transmissions. The Davies Craig Transmission Oil Cooler range and corressponding hoses supplied in each kit are compatibale with all known ATF commercially avilable around the world.

When running the booster directly off a battery (car or caravan), we recommend having a switch so that it does not drain the battery when not in use. This will prevent unnecessary wear on the battery system.

The alternative is to set up a solar system for the battery.

The short answer is YES, you can connect the fan into the stock wiring.

Just be mindful of the fuses used for the stock fans, these may need to be changed to suit the new fans.

You will not have any issues powering the 2 fans of you 20A power supply as the fans will only draw the current required to run.

It will not supply the fans with 20A as the current supplied by the power supply is determined by the requirements of the load, in this case the 2 fans.

|

Display behaviour |

Diagnostic |

solution |

|

Err 1 |

Temp sensor short circuit |

Replace unit |

|

Err 2 |

Temp sensor open circuit |

Replace unit |

|

Constant incorrect reading of 120c or 248f |

Temp sensor short circuit |

Replace unit |

|

Flashing display / unit re-setting |

Might not operate correctly |

Check ignition source location. If the ignition is connected to the coil or another similar source Must be constant +ve source. Test by connecting to battery +ve as this will provide constant power. If direct battery connection solves issue, re-locate ignition wire to better location (preferably direct from ignition under dash) |

Yes you certainly can without any issues.

When using an EWP/Fan controller you need to wire directly to the battery.

Waterless Coolant puts extra strain on the electric motor and can cause it to overheat and reduce its life. The viscosity of that type of the coolant is the issue and is not recommended for EWP’s

"Waterless coolants increase the load on an EWP and may reduce pump life"

When mounting your Transmission Oil Cooler, you can mount it in any orientation.

The air in the cooler will be forced out by the thick transmission fluid as it is pumped through the system. You do not need to pre-fill the cooler as the pressure in the system is sufficient to remove the air.

Yes, you can use the A/C wire as a manual override by providing it with 12V from a switch.

There is a 10 second delay between fan 1 and fan 2, if the temperature is dropped to the shut off point in this time then fan 2 will not turn on for very long this is totally normal.

The #0444 is not designed to operate after the car is shut down, it can be wired in such a way to have it run for a period of time after the ignition is turned off but it requires added wiring and a time delay relay.

It is not necessary to run fans after engine shut off unless there is an electric pump providing coolant flow through the radiator otherwise you are simply cooling the same water/coolant in the radiator and it is not circulating.

The unit is powered by the ignition. To have the unit come on when the ignition is on (but engine not started) you need to connect the ignition wire of the unit to a positive source that is on when the ignition is on.

Do not wire the ignition line to any 12V source, if you connect the unit to the ignition coil, ECU/computer or any other load it will cause issues, like you’re having

I suggest wiring directly to the ignition source for the best results.

Part #0465 is designed to fully replace the temperature probe on the latest version of the Digital Thermatic® Fan Switch Kit - part #0444.

The new version has a bullet style connector in the temperature sensor wires that allows for the sensors to be swapped out if they get damaged, or changed to the threaded type.

If your unit has the bullet connector then you can simply pull the prob style sensor out and connect the #0465 into the connector.

If your unit does not have this connector then you will need to get part No. #0418 which is a brass fitting designed to hold the prob in the coolant.

When it comes to choosing a frequency, it really depends on your system, what it can handle and how you intend to wire it.

In general, low frequencies put less work on the control circuit but you sacrifice precise control at low speed and can also produce noise.

Higher frequencies give better control at low speed but can cause the control circuit to overheat and reduce life.

To choose the best frequency is really a trial and error process, once you have dialled in the frequency you control the speed on the pump by adjusting the duty cycle on the PWM signal.

**A reminder, we hold international patents for a Digital Controller that will manage the operation of the EWP® by varying the speed of the pump in response to the coolant temperature.

The function graph is only a guide for the operation on the controller and not a 100% accurate representation.

The correct operation graph would be confusing to many customers. As we use PWM to control the pump speed there is a start up point (shown as 0V on the graph) and 100% speed (shown as about 13V)

The 6V of the pulse mode is the 50% full speed mark between the start point and 100%.

Meaning there can be a little difference in actual voltage readings. the voltage is not able to be accurate measured with a multi meter because of the PWM control method.

It sounds like it is constantly rebooting.

The cause is that you have wired the controller up incorrectly by wiring the ignition directly to the ignition coil and not an ignition switched source like accessories. To test simple wire the ignition directly to battery positive, if this solves the issue simply re-locate the ignition wire.

The reason that your having this issue is because the electronics of the switch draw power for the ignition wire so the voltage needs to be constant and stable.

The ignition coil is not always a constant voltage, and it pulses in relation to the ignition cycle (unsuppressed) meaning it is neither constant or stable.

This can also be the same or similar for the distribution block due to other loads on the system.

What is happening in your case is that the voltage is dropping and causing the unit to power down, this voltage drop happens every 3 seconds

You can always try running the ignition through a relay controlled by the distribution block to connect the unit to the battery. This should help filter the “noise” in the ignition wire

The #8001 Digital controller does not have a built in A/C override, however it can be achieved be wiring the fans as shown below.

Alternatively, you can use a 5-pin relay for the A/C override to switch pin 85 of the fan relays between the controller (coil not powered) and ground.

The connections for this would be. This does depend on the relay used

|

A/C Relay pin |

connection |

|

30 |

Pin 85 of Fan relays |

|

87 |

Negative ground |

|

87A |

Digital controller green and black wire |

|

85 |

Negative ground |

|

86 |

A/C clutch/signal |

If it was professional installation, we suggest you take the unit back and get them to find / fix the issues ( they may be able to re-pin a bad connection in the plug)

You need to check all connections are tight as vibrations can cause connections to become loose.

Main areas that would cause this are

- Ignition wire, also it CAN NOT be connected to the ignition coil this could also cause the problem.

- Ground connection

Check all connections are solid (by manually bouncing/wriggling them quite vigorously) this needs to be done at the connection point not the plug. If any connections are loose, he needs to tighten them up.

Check the earth connection and ensure it is in solid contact with bare metal and that the main battery earth is connected properly.

It would also be a good idea to check that no wires have been damaged or kinked.

If the above dose not find a solution, isolate the loom (by holding the loom tightly so it can’t move about 3” front the plug/control unit) and first test again by moving the whole unit.

If this causes the issue, check all wires are secure in the plug by pushing then into the connector.

If a replacement unit is needed, you will need to re-wire the entire setup without cutting and joining any wiring. If you are able to locate the exact cause, then it may avoid the need to replace anything. To isolate the part that needs replacing.

As a general rule on any Davies, Craig digital switches/controller with below issues:

- Flashing display

- Constant resetting

- Any periodic behaviour E.G, problem happens every 3 seconds or similar

Check the ignition location, if it is connected to the ignition coil or another source that has a reasonable load on it could be the cause.

A simple test for this it to connect the ignition wire directly to battery positive, if it operates correctly then they need to relocate the ignition to an ignition switched source like the accessories.

The design of a centrifugal pump means that the Max flow through the system is determined.

The best way to visualise how a centrifugal pump works is to think of it like pushing a weighted box across a rough surface.

If you apply a constant force (or voltage) and the resistance (system resistance) of the surface is constant, then once moving, there is a pre-determined maximum speed the box can move.

If you change the force applied, the maximum speed will change the same will happen when the resistance changes. This will also occur when voltage and system resistance changes.

From the below flow chart, you can estimate the flow rate through the system by looking at where on the flow curve and the system resistance intersect.

We assume you are using our EWP/Fan digital controller, if not, then all our fan switches are not designed to run after ignition is turned off. This is because without coolant flow there is no point in running a fan as it does not provide any real benefits.

When wiring a digital controller up with a kill switch, as long as you wire up as per instructions meaning the power wires are connected directly to battery positive, the function will not be affected. The ignition wire s only a signal wire and power for the unit is taken form the battery. If you are required (by safety regulations) to have all system connected to the kill switch then the function will not run.

The overrun will only be affected when the kill switch is disconnecting the battery. This mean that if you want the overrun function to work, you just need to leave the switch closed until the controller fully shuts down. If the ignition is wired directly to battery positive without being switched by the ignition, then the unit will not preform the shutdown/overrun function as the ignition has a constant positive 12V signal.

In situations where high system pressure is an issue, we recommend looking at using two of our electric water pumps in series.

Example:

Q: I require 5 gpm (18.9L/m) @ 15psi

A: We recommend two of our EWP115 pumps in series which will provide 8gpm @ 15psi or 5gpm at 17-18psi

It is very important that you understand that our 12 Volt pumps are rated to a MAX voltage of 15 Volt. With that said, our EWP’s use a brushed motor and can be used at higher voltages but the life will be affected.

Running a pump off 16 Volt system although not ideal, won’t be to detrimental to the life of the pump, however running at a voltage above this could cause a significant reduction in life.

You could look at installing a voltage regulator to drop the voltage to protect the pump.

If you were to run a 24V pump the Max performance at 16V will be about 33% less 25GMP (100L/min) .

The lower flow for the 24V pump should not make much difference during a run, and the extra voltage when charging won’t be of any concern and the performance will be increased.

Ultimately the choice is up to you, the 12V pump will have a higher flow but the risk of damaging the pump is higher whereas the 24V pump only has a reduction in performance.

Also, there is nothing stopping you from installing multiple pumps, this would be quite beneficial if running 24V pumps.

Yes, you can run 2 pumps in series, however I would look at using a thermal switch to control the flow of the second pump.

The use of a thermal switch will allow you to always have the additional flow needed and can assist is catching any overheating issues.

The EWP is best mounted as low as possible as this assists in the bleeding process as the EWP is not self-priming.

In general, mounting the EWP in a higher position is not an issue provided it is properly bled of all air before it is turned on.

It is also good practice to try mount the EWP as far away from any heat sources (like the exhaust) to help protect the pump from ambient heat exposure.

Firstly, when the probe is installed in the fins of the core there will be a certain degree of temperature difference (we estimate 15 deg C ) between the coolant temperature and the fin/core radiant temperature. This difference is by no means an inaccuracy but it does need to be accounted for when setting and reading the unit.

But to answer your question: No, you cannot cut the temperature prob off and connect it to the sensor of your existing gauge doing this will likely result in errors that will result in the unit not functioning correctly.

The only way to fix these errors would be to replace the unit. If you wish to read the coolant temperature then you MUST use the temperature sensor adaptor kit (part #0409) to install the prob into the top radiator hose. This will allow you to read the coolant temperature rather than the ambient temperature of the core.

You are correct the system is operating exactly as it is designed. The problem with a thermosyphon car is that they generally don’t produce as much heat and the system has a quite small flow rate.

What I normally recommend for customers installing an EWP in a thermo syphon car is to install the EWP and fan and have both controlled by a #0444. When wiring the fan is wired to FAN1 and the EWP to FAN2. What this does is it runs the fan as required but if this is not enough then it switches the EWP on after 10 seconds.

This can further be improved upon with the release of the #0500 paired with the #0465.

The #0500 has independent set temperature allowing the system to be fine tuned to achieve the best cooling performance.

A way to allow the car to get up to temperature without needing to restart the can after 5 minutes is to install an #0401 on the controller’s ignition line and set it to as low as possible, what this does it creates a temperature-based time delay.

By doing this what happens it the #0401 keeps the controller off until the temperature reaches 40degC at this point the 0401 switches and the controller will turn on.

Let us give you some information on the function of the radiator pressure vent.

When the coolant or water gets hot it expands this results in a pressure increase another cause of pressure increase comes from the water pump (mechanical or electric).

The vent pressure rating is determined by several factors:

- Pressure caused by the hot coolant at normal/slightly above normal operating temp

- The pressure (resistance to flow) caused by the water pump and the components in the system (i.e. the radiator)

- The Maximum safe pressure of all components plus a safety factor

When the coolant pressure and pump pressure are added together you get the total system pressure.

When the pressure is high enough it opens the pressure vent valve and coolant is allowed to escape the system (overflow) to reduce pressure.

In most cooling systems this coolant isn’t lost but stored in an overflow bottle/tank.

When the pressure drops a vacuum is created. The radiator cap also has a vacuum relief valve. When the pressure/temperate is reduced and vacuum relief valve opens to prevent a vacuum forming.

When this happens the coolant that is in the overflow bottle is sucked back into the cooling system to keep the system full. If there is not an overflow system installed air will be sucked into the system.

So, your problem is that the added pressure (resistance to flow) from your new radiator and upgraded components, when added to the pressure form expanding coolant is causing the system to vent. If you have a correctly installed overflow system and you’re not losing coolant and able to maintain temperature then there is no real problem. However, if the system is venting lots of coolant regularly then you may need to get a higher rated pressure cap.

If you don’t have an overflow or expansion tanks system installed then I recommend installing one. After this you can look at the pressure rating of the radiator cap.

If the current cap is only venting when well above (5C+) the target/ operating temp then you shouldn’t need a new cap. If the cap is venting at operating temp or slightly above (less than 5C) then a higher rated cap may be needed.

Using the EBP23 and the #8001 controller is not recommended as we cannot guarantee a usable flowrate at 6V.

This is because the start up voltage of the EBP23 is 5V so when running at 6V there may not be enough head pressure to move the water though the system.

We recommend using one of our switches to run the booster pumps such as part numbers 0401, 0444 & 0500

You can shorten the wiring on the Digital Controller excluding the sensor wire.

Our recommendation is that you wind up the wiring and not cut.

Regarding the sensor wiring: PLEASE MAKE SURE you DO NOT cut the Sensor / Probe wiring to shorten or extend while installing. This action interferes with the resistance signal to the control box and subsequently an 'err' message will appear.

We suggest you wind up the wiring should you need a shorter the lead.

The EBP25 (#9025) cannot be used with the #8001 Digital controller as it requires a minimum of 8V before it will operate.

The use of an EBP15, EBP23 or EBP40 with the #8001 Digital controller is not recommended as we cannot guarantee any usable flowrate at 6V.

This is because the start-up voltage of the EBP15, EBP23 and EBP40 is around 5V so when running at 6V there may not be enough head pressure to move the water though the system.

We recommend using one of our Thermatic switches such as part numbers 0401, 0444 & 0500 to control electric booster pumps.

Whilst all 3 can be measured as a pressure value, they are not interchangeable. Understanding the difference between them is critical to getting the most out of your Electric Water Pump

System Pressure is the measure of how much the coolant has expanded due to the increase in temperature, this is important because as pressure increases, so does the boiling point of your coolant. it is also very important that the system pressure does not exceed the max pressure rating of components to prevent damage. in a typical automotive cooling system this is done by the radiator pressure cap.

Head pressure is the measure of how much energy a pump can impart into the coolant. This pressure is not the same as System Pressure as it is the differential pressure between the inlet and outlet of the pump. Head Pressure can also be called Head Height, basically the maximum vertical distance the pump can pump a fluid.

Pressure Drop or System Resistance is simply the measure of how much energy (Head Pressure) is required to move coolant though the system at a given flowrate. The System Resistance is often shown in the System Curve this curve shows the Head pressure required for any given flowrate,

Whilst the 3 values are not interchangeable, they are all equally important when selecting the right pump for your application, the System Resistance and Head Pressure are used to find a suitable pump, while the system pressure is determined by the maximum pressure the pump can withstand without damage.

The ignition (yellow wire) needs to be connected to a switched positive source.

As long as the ignition is receiving a positive voltage the exact source (direct battery or elsewhere) should make little difference.

However, for positive earth vehicles we recommend that the ignition be wired direct to battery positive though an on/off switch.

The switch can be a battery cut off switch or an ignition controlled relay.

The #0444 will not need to be reset when disconnected from power.

If you are using the EWP as an Auxiliary Pump supporting and mechanical pump, you could connect the pump to the ECU and use the fan circuit which would turn the pump on and off with the fans.

If you are using the EWP as the main cooling pump and removing the mechanical pump, you will need the Davies Craig EWP Controller.

Heat exchangers and radiators work in the exact same way. Only with a heat exchanger the air is being cooled not the fluid. It is quite common for these systems to not run a thermostat, the reason for this is that you are not trying to maintain a constant coolant temp unlike a radiator. This means you want the coolant to be as cold as possible meaning you want as much flow as possible.

When selecting you pump there are a few things to consider,

Hose size

Power output

For a heat exchanger system that is using ¾” (19mm) hose the best range of pump is the EBPs in particular the EBP25 and the EBP40

For a Stock performance supercharger I would look at the EBP25 or EBP40, for a higher performance system then the EBP40 is going to be better.

If you have larger diameter hoses like AN16 lines then I would recommend on of our EWPS in particular our Alloy EWP115 and EWP150 as these units have built is -16AN ORB fittings in the inlet and outlet to allow easy adaption to AN16 braided lines.

For stock-mid range performance the EWP115 Alloy is a good choice, but the EWP150 is going to perform very well in the power range.

If you have a rear mounted tank or a high performance blower then the EWP150 is going to be the best choice.

“Water pressure is a measure of the force that pushes water through the mains and into your pipes. It is measured in ‘bars’ – one bar is the force needed to raise water to a height of 10 metres.”

“ System Pressure is the measure of how much the coolant has expanded due to the increase in temperature, this is important because as pressure increases, so does the boiling point of your coolant. it is also very important that the system pressure does not exceed the max pressure rating of components to prevent damage. in a typical automotive cooling system this is done by the radiator pressure cap.”

The Max pressure rating that we quote is related to system pressure, this is the maximum amount of force that can be exerted on the housing before the pump bursts or begins leaking. The mains pressure should have little to no effect on this because it is essentially the head pressure of the mains supply pump.

If the mains pressure is above the Max pressure this should not be an issue as far as I am aware, because the mains pressure is the force applied to the water and not the force exerted by the water due to expansion.

Yes, but in many cases this will provide no benefit unless your fans draw over 30A continuous, in which case a relay with a higher Amp rating can be used.

The relay socket on the switch is rated to 40A continuous draw, this will not be affected by the rating of the relay.

The start up current handling ability is rated at 60 Amps (same as our 16" Fan, part #0166) and has completed over 10,000 test cycles under these conditions.

It is also important to note that there are very few, if any fans on the marker that draw over 35A continuous.

This means that the standard relays included in our fan switches, part #0444 & 0445 are appropriate for the majority of electronic fans on the market without the need for modification.

We recommend installing the sensor anywhere on the hot side of the cooling system.

This can be the Thermostat housing, radiator or you can even utilise unused ports in the engine.

If you are not running a heater, you can always use the heater outlet from the engine to install the sensor.

Given our fans are reversable, you need to ensure the fan blade rotates in the correction direction when mounting upstream or downstream.

If the fan blade is rotating in the opposite direction (trailing edge leading) this causes a significant increase in blade RPM.

This increase in RPM will result in a significant increase in noise.